Learning Content

Thermoplastic Textures

Kydex

P1 Haircell – The most popular texture (Holsters/Sheaths) and what some would call the “industry standard”.

- Contains some texture and some shine (Most, if not all, solid colors will be available in this finish)

- Best abrasion resistance

- Excellent for high abuse areas

PC Level Haircell – The second most popular texture (Holster/Sheaths), contains slightly less texture and shine when compared to the P1 finish (available in some colors)

- Leatherette appearance

- Good scratch resistance

- Common for high abuse areas

- Easy to control gloss level when thermoforming

P3 Velour Matte – Contains the most texture of our 4 offerings (Only stocked in the black color)

- Excellent abrasion resistance

- Easy to control gloss when formed

- Most widely specified texture for aircraft components

- Remains very “matte” if formed properly and can have a “painted composite panel” look.

P8 Suede – Contains the least amount of texture of our 4 offerings (Only stocked in the black color)

- Good abrasion resistance but can show marring in light colors

- Excellent for textured female molding

- Great for flat laminations but can “gloss up” when vacuum formed

Boltaron

HC – The most popular texture (Holsters/Sheaths) and what some would call the “industry standard”.

- Contains some texture and some shine (Most, if not all, solid colors will be available in this finish)

- Best abrasion resistance

- Excellent for high abuse areas

Thermoplastic Styles

Kydex T – The most popular style (Holster/Sheaths) and what some would call the “industry standard”.

- Superior Impact Resistance

- Among the most rigid of thermoforming materials

- Easy to form with excellent part definition and deep-draw characteristics

Kydex 100 – The less popular style (Holster/Sheath) which is not as cost-effective as other styles available; but offers the highest standards when compared to less expensive thermoplastic materials.

- Meets highest standard for chemical resistance for thermoplastic materials

- Uniform wall thickness and crisp detail

- Good for deep or hard to form parts

Boltaron 4335 – The most popular style (Holster/Sheaths) for solid colors and what some would call the “industry standard”.

- High flexural strength, modulus

- Uniform wall thickness in deep draw forming

- Consistent thermoforming characteristics

Boltaron 4332 – This style is available on solid colors and is also used on Carbon Fiber and other “technical textures”

- High impact and chemical resistance

- Uniform surface and forming consistency

- Versatile assembly and bonding techniques

Thermoplastic Heating

Heating Temperatures

- When heating Kydex/Boltaron, the temperature range will be between (330-400°F). The heating temperature will vary depending on the thickness of the thermoplastic, altitude, and humidity levels in your area.

Fabric Covered Kydex

- Due to the wide range of Thermo manufacturing, we can only make recommendations based on our test market feedback during the R&D process and continual feedback from our current customer base. This material may not be for the novice Kydex® Thermoformer, if you are new to the forming process we suggest you dial in your process with less expensive and sensitive material first and then move to a product such as this which may be less forgiving.

- It is recommended that thermoformers not use a membrane-less vacuum press for this application, due to the potential for fabric separating from the base material during this process.

- Due to the fabric press & cut assembly process there will be a material gap of appx 1/16”- 1/8” around the edges of the Kydex® material.

- It is recommended that when using a single sided heating oven/element, that heating the back (non-fabric side) of the sheet material is ideal.

- To prevent excess fraying when drilling, a brad point drill bit is recommended.

- It is recommended to use a sheet parchment paper between the fabric side and press membrane or foam to prevent material from sticking.

WTG vs. Standard Grain Orientation

-

WTG (With The Grain) Orientation – We offer this grain orientation as an option on both our MultiCam Original and Black Ultra Matte patterns. During the infusion process, the pattern is laid down in the same direction as the grain orientation of the Kydex sheet. Some clients report that this cuts down on the shrinkage of the pattern, but it is ultimately a matter of preference when it comes to the difference between the two grain orientations.

-

Standard Orientation – The standard orientation is used on all prints except for the MultiCam Original and Black Ultra Matte WTG patterns mentioned. The pattern is laid down against the grain orientation of the Kydex sheet. This is the most commonly used orientation and is considered the “industry standard”.

GS Eyelets

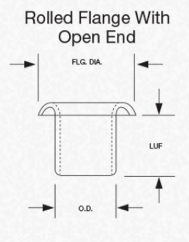

Eyelet Sizing Structure – The eyelet size will be configured by the following 3 dimensions:

- Outside Diameter

- Length Under Flange

- Flange Diameter

-

**Our two available sizes are 3/16” & 1/4” (Outside Diameter)**

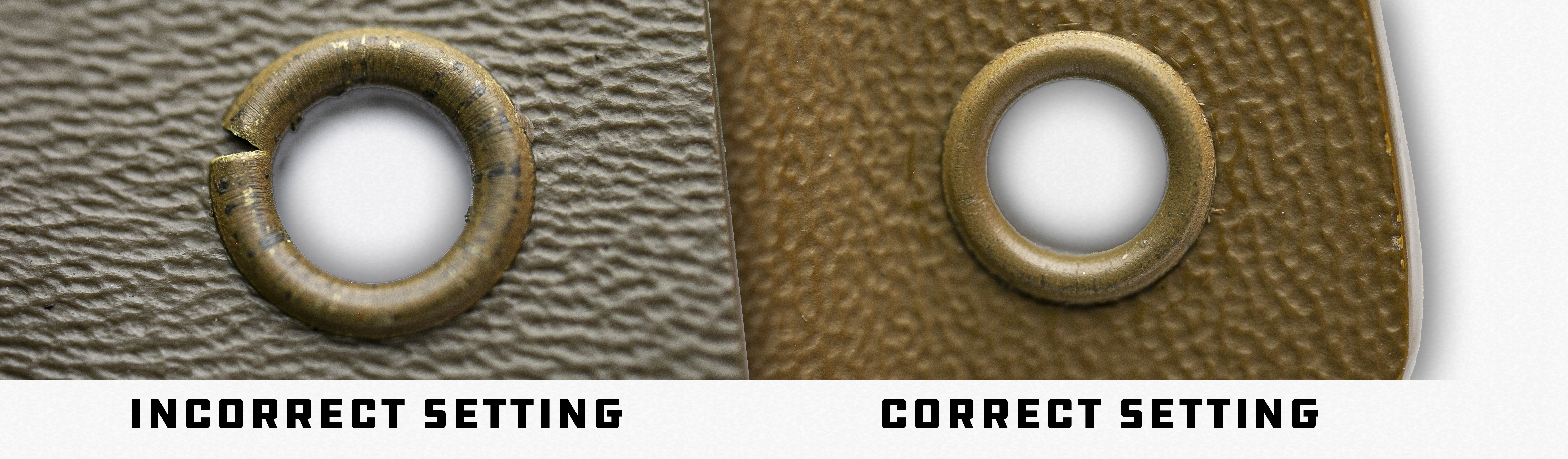

Eyelet Setting – There are a multitude of different ways that eyelets can be set, the most popular forms are listed below. The proper setting of eyelets and setting tools/dies is critical in order to maintain consistency and produce quality rolling.

- Manual Hand Press

- Manual Kick Press (available for purchase online)

- Hand Setting Tool (available for purchase online)

- Dies (available for purchase online)

Eyelets (Splitting & Chipping)

There are many factors that can come into play if you are experiencing any splitting and/or chipping on your eyelets. If you are experiencing any splitting on your eyelets, please first check to see if your dies are properly calibrated and in good working condition. If they are, the most common reason for splitting is due to the eyelet length being too long for the application. If possible, try using a shorter eyelet and also double-check the thickness of your sheet material (some batches run thinner than others). If all those steps have been followed and the problem still persists, contact our sales department for further help.

Machine Screw Head Types

Index Carries the following Machine Screw Head Types:

- Flat Head Screw

- Oval Head Screw

- Pan Head Screw

- Truss Head Screw

- Flat Truss Head Screw

-

Button Head Screw